We are introducing an amazing new product which enables you to create beautiful candles using old (or new) cooking oil. Called the Greatest Candle in the World It comes in a tin which contains scented candle powder, wick holders and candle wicks and a scoop for measuring the powder.

You will also need:-

a. A glass to make the scented candle in.

b. A metal tin or baking tray (just to keep things tidy!)

c) Approximately 100ml Cooking Oil (used or new).

d.A jug or container in a microwaveable material (glass or ceramic). It will be hot when it comes out of the microwave so use a container with a handle.

Making the Candle:-

1) (only if you are using up old oil, if using fresh cooking oil skip this step). Filter you oil oil through a coffee filter or small screened colander. If possible let the oil rest for 24 hours before recycling it to make sure the old particles are separated from the oil.

2. Pour the oil into the jug and pour one heaped scoop of scented wax powder/

3. Microwave for 1-2 minutes on Medium power

4. Using your oven glove remove from microwave and add a further 2 heaped scoops and stir until dissolved.

5.Pour the oil/candle powder mix into your glass.

5.Pour the oil/candle powder mix into your glass.

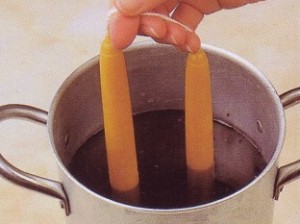

6. Place the candle wick using the cardboard wick holder into the oil/wax. Be care as the oil will be HOT. Use a pencil or other long object to make sure the wick is placed centrally at the bottom of the glass.

7. Let the candle cool until solid (this does not take long, 5 to 10 minutes).

7. Let the candle cool until solid (this does not take long, 5 to 10 minutes).

Now you have a lovely scented candle! The kit contains enough ingredients to make at least six candles. Please watch our video on you tube